OSHA electrical safety standards protect lives and ensure compliant solar installations across America. Download the latest OSHA electrical safety standards PDF to access comprehensive guidelines on proper lockout/tagout procedures, arc flash protection requirements, and essential personal protective equipment (PPE) specifications. These federal regulations establish critical safety protocols for both professional installers and homeowners undertaking solar projects, helping prevent electrical accidents and ensuring code compliance.

For solar professionals and property owners alike, understanding these standards isn’t just about meeting legal requirements—it’s about creating a safer working environment and protecting long-term investments. The standards cover everything from proper grounding techniques and wire management to specific clearance requirements for electrical equipment. Regular updates to these guidelines reflect new safety challenges and technological advancements in the renewable energy sector.

By following OSHA’s detailed electrical safety protocols, installers can maintain workplace safety while homeowners gain peace of mind knowing their solar installation meets federal safety requirements.

Key OSHA Electrical Safety Requirements for Solar Installations

Personal Protective Equipment (PPE)

When working with electrical systems, proper Personal Protective Equipment (PPE) is essential for your safety. OSHA standards require specific gear based on the voltage levels and type of work being performed. For basic electrical work, you’ll need insulated gloves rated for the appropriate voltage, safety glasses with side shields, and non-conductive safety boots. A hard hat is necessary to protect against falling objects and electrical hazards from above.

For added protection, wear fire-resistant clothing made from natural fibers or specially treated materials. Avoid synthetic fabrics, which can melt and cause severe burns. Your clothing should fit properly – not too loose to catch on equipment, but comfortable enough for movement.

Remember to inspect all PPE before each use. Look for tears, holes, or signs of wear in gloves. Replace any damaged equipment immediately. Store PPE in a clean, dry place away from direct sunlight and extreme temperatures. By properly maintaining and wearing your safety gear, you significantly reduce the risk of electrical injuries while staying compliant with OSHA regulations.

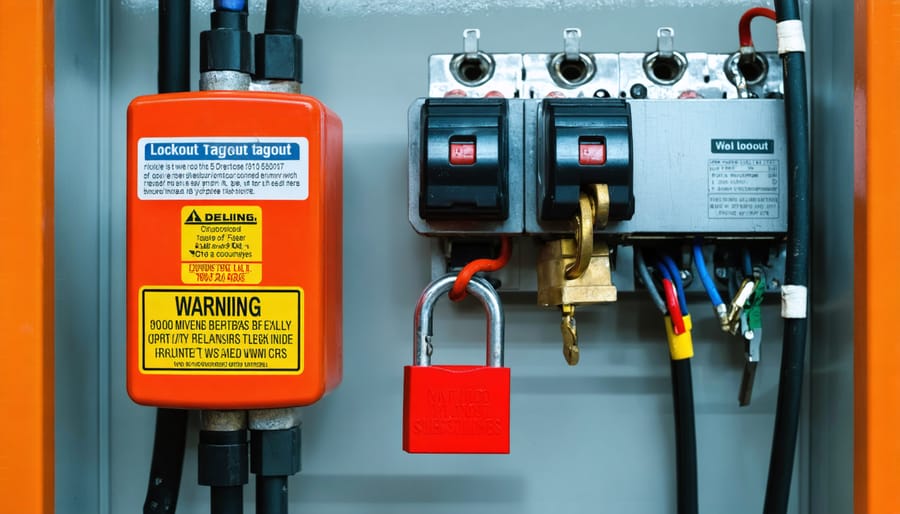

Lockout/Tagout Procedures

OSHA’s Lockout/Tagout (LOTO) procedures are essential safety protocols that protect workers from dangerous electrical energy during maintenance or installation work. Before starting any electrical work, workers must completely disconnect and de-energize the system, then secure it with a lockout device to prevent accidental reactivation. Each worker should attach their personal lock and identification tag to the lockout device.

The tag must clearly state “Do Not Operate” or similar warning language, along with the worker’s name and the date. Only the person who installed the lock and tag is authorized to remove them. For complex systems with multiple energy sources, a detailed checklist should be followed to ensure all power sources are properly secured.

After applying locks and tags, workers must verify that the system is truly de-energized by testing with appropriate voltage meters. All stored electrical energy must be safely discharged before work begins. When work is complete, a systematic process for removing locks and tags and restoring power must be followed, including notifying all affected workers and performing a final safety check.

Remember, proper LOTO procedures are not optional – they’re a critical safety requirement that saves lives and prevents serious injuries.

Electrical Safety Best Practices for Homeowners

System Monitoring and Maintenance

Regular system monitoring and maintenance are crucial for ensuring electrical safety compliance in solar installations. Start by implementing a monthly visual inspection routine of all electrical components, including cables, connectors, and junction boxes. Check for signs of wear, damage, or loose connections that could pose safety risks. Following surge protection guidelines is essential to safeguard your system against power fluctuations.

Keep detailed maintenance logs documenting all inspections, repairs, and replacements. This documentation helps track system performance and demonstrates compliance with OSHA requirements. Schedule professional maintenance checks at least annually, focusing on testing ground fault protection devices, checking inverter performance, and verifying proper system grounding.

Clean electrical enclosures regularly to prevent dust accumulation, which can create fire hazards. During rainy seasons, pay special attention to weather seals and ensure water isn’t penetrating electrical components. Remember to always power down the system before performing any maintenance work and use appropriate personal protective equipment (PPE) as specified in OSHA guidelines.

Emergency Procedures

In the event of an electrical emergency, quick and appropriate action is crucial. If you witness an electrical accident, first ensure your own safety by staying clear of the affected area. Never touch someone who is in contact with live electricity – instead, immediately shut off power at the main breaker or fuse box if safely accessible.

For electrical fires, remember that water should never be used. Keep a Class C fire extinguisher readily available and know how to use it. When implementing fire safety prevention measures, ensure all escape routes are clearly marked and unobstructed.

Call emergency services (911) immediately for serious electrical incidents. While waiting for help, only provide first aid if you’re trained and can do so without risk. For minor electrical burns, run cool (not cold) water over the affected area for at least 10 minutes.

Keep an emergency contact list posted near your electrical panel, including utility company numbers and qualified electricians. Document all incidents and maintain an up-to-date first aid kit specifically equipped for electrical emergencies.

Working with Certified Installers

When it comes to electrical safety in solar installations, working with certified installers who follow OSHA standards isn’t just a recommendation—it’s essential to protect your solar investment and ensure your family’s safety. Certified installers bring more than just technical expertise; they bring peace of mind through their comprehensive understanding of OSHA electrical safety requirements.

Look for installers who maintain current OSHA certifications and can demonstrate their compliance with safety standards. These professionals should readily provide documentation of their training and certification status. Quality installers will perform thorough site assessments, use proper personal protective equipment (PPE), and follow detailed safety protocols during installation.

A certified installer will:

– Conduct comprehensive electrical safety inspections

– Use OSHA-approved tools and equipment

– Follow proper lockout/tagout procedures

– Implement fall protection measures

– Maintain detailed safety documentation

– Provide clear safety instructions for homeowners

Before hiring an installer, ask to see their OSHA training certificates and safety records. Reputable companies will happily share this information and explain their safety protocols. They should also provide you with clear documentation of the installation process and safety measures implemented in your system.

Remember that choosing an OSHA-compliant installer might cost more initially, but it’s an investment in the long-term safety and reliability of your solar system. These professionals help ensure your installation meets all current safety standards and local building codes, potentially saving you from costly repairs or safety issues down the line.

Documentation and Record-Keeping

Maintaining proper documentation is a crucial aspect of electrical safety compliance. OSHA requires keeping detailed records of all electrical safety inspections, maintenance activities, and employee training sessions. These records serve as proof of compliance and help track safety improvements over time.

Key documents to maintain include equipment inspection logs, maintenance schedules, and repair records. Each electrical installation should have its own documentation file containing installation dates, specifications, and any modifications made. Training certificates and attendance records for safety meetings must be kept for at least three years.

For homeowners and small business owners, creating a simple documentation system can help ensure safety and compliance. Start with a basic log book recording inspection dates, findings, and any repairs made. Keep copies of all electrical permits, contractor licenses, and equipment warranties in a dedicated folder.

Digital record-keeping tools can streamline this process. Many mobile apps now offer easy ways to track maintenance schedules and store important safety documents. Photos of electrical installations and repairs can be particularly helpful for future reference.

Remember to regularly update your safety documentation and ensure it’s easily accessible to relevant personnel. In case of an OSHA inspection or insurance claim, having well-organized records demonstrates your commitment to electrical safety and can help protect you from potential liability.

Electrical safety is not just about following rules—it’s about protecting lives and ensuring a secure working environment. Throughout this guide, we’ve covered essential OSHA electrical safety standards that serve as your roadmap to creating a safer workplace. Remember that proper lockout/tagout procedures, regular equipment inspections, and appropriate PPE usage form the foundation of electrical safety practices.

Make these safety standards an integral part of your daily operations by maintaining updated documentation, conducting regular training sessions, and fostering a culture of safety awareness. Keep your OSHA electrical safety standards PDF readily accessible to all team members and ensure it’s regularly reviewed and updated.

Your commitment to electrical safety protects not only your workers but also your business’s reputation and compliance status. By implementing these standards consistently and thoroughly, you create a workspace where everyone can perform their duties with confidence and security. Stay proactive in your approach to safety, keep communication channels open for safety concerns, and never compromise when it comes to following proper electrical safety protocols.

Remember: a safe workplace is a productive workplace, and electrical safety is everyone’s responsibility.