Solar panels don’t have to become tomorrow’s waste problem. Circular solar panels are designed from the ground up to be recycled, refurbished, or repurposed at the end of their 25-30 year lifespan, turning what many fear is an environmental liability into a closed-loop system that actually strengthens the case for going solar.

The solar industry is rapidly moving beyond the old “make, use, dispose” model. Today’s leading manufacturers are engineering panels with easily separable components, using materials that can be recovered at 95% efficiency, and establishing take-back programs that guarantee your panels will never see a landfill. This isn’t just good for the planet—it’s increasingly good for your wallet, as some companies now offer trade-in credits and extended warranties for circular-designed systems.

If you’ve hesitated to install solar because you’ve heard about a looming waste crisis, here’s the truth: that problem is being solved right now through innovative design and proven recycling technology. Understanding circular solar panels means recognizing that your investment today supports not just clean energy generation, but a sustainable system that will benefit homeowners for decades to come.

The Solar Panel Waste Problem Nobody Talks About

Here’s something most solar panel manufacturers won’t advertise upfront: those sleek panels on your roof have a lifespan of about 25 to 30 years. After decades of faithfully converting sunlight into electricity, they eventually retire. And here’s where things get interesting.

The first big wave of solar panels installed during the early 2000s boom is approaching retirement age right now. We’re talking about millions of panels that will need proper handling in the coming years. Currently, most retired panels end up in landfills because separating their valuable materials—like silicon, silver, aluminum, and glass—has been expensive and complicated.

But before you worry, here’s the good news: this isn’t a looming environmental disaster. It’s actually one of the biggest opportunities in the renewable energy industry.

Think of it like the early days of plastic recycling. At first, nobody had systems in place, but once we recognized the value, entire industries emerged to capture it. The same transformation is happening with solar panels, only faster and smarter.

Traditional disposal methods fall short because panels were designed with performance in mind, not end-of-life recovery. They’re essentially sandwiches of different materials sealed together so tightly that separating them damages the valuable components inside. It’s like trying to un-bake a cake—technically possible, but messy and wasteful.

This realization has sparked a revolution in panel design. Engineers and manufacturers now understand that truly sustainable solar means planning for a panel’s entire lifecycle from day one, not just its productive years. That’s where circular design comes in, transforming what could have been a waste problem into a resource goldmine.

What Makes a Solar Panel ‘Circular’?

Think of most products you buy today: they’re made, you use them, and when they break or become outdated, they end up in a landfill. That’s the traditional “linear economy” at work—a straight line from factory to trash heap.

Circular design flips this wasteful model on its head. When solar panels are designed with circularity in mind, manufacturers think about the entire lifecycle before the first panel ever rolls off the production line. They ask: How can we make these panels easier to repair? Which materials can be recovered and reused? How do we design connections that can be taken apart rather than permanently sealed?

The difference is profound. Traditional solar panels weren’t designed with their eventual retirement in mind. They use adhesives that permanently bond layers together, making separation nearly impossible. Materials get mixed in ways that complicate recycling. When these panels reach the end of their 25-30 year lifespan, recovering valuable materials becomes expensive and labor-intensive.

Circular solar panels, by contrast, are built for multiple lives. Manufacturers use mechanical fasteners instead of permanent glues. They choose materials that are easier to separate and process. Components are standardized so they can be swapped out for repairs. Some companies even design panels that can be refurbished and resold rather than scrapped.

The result? Less waste, lower long-term costs, and solar technology that truly lives up to its environmental promise from start to finish.

Breakthrough Innovations Making Solar Panels Recyclable

Easier-to-Separate Materials

One of the most exciting breakthroughs in circular solar panels is the shift to easier-to-separate materials. Traditional solar panels are built like sandwiches, with layers glued together so tightly that taking them apart is nearly impossible without damaging the valuable components inside. Think of it like trying to separate the layers of laminated paper—you end up tearing everything.

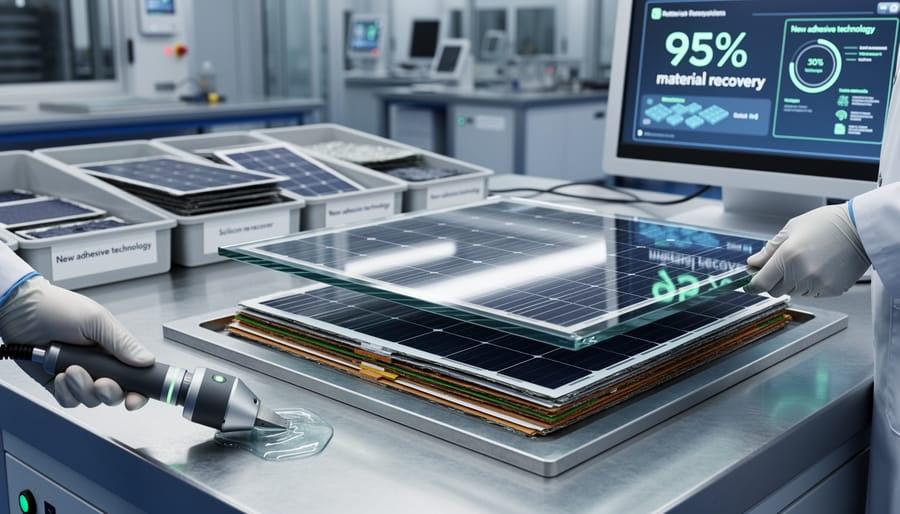

Newer circular panels use innovative adhesives and lamination techniques specifically designed for disassembly. These special bonding methods hold everything securely during the panel’s 25-30 year lifespan but can be separated when it’s time for recycling. Some manufacturers use heat-reversible adhesives that release their grip when warmed to specific temperatures, while others employ mechanical fastening systems that can be unfastened without tools.

The improvement is remarkable. With old recycling methods, you could typically recover about 80% of materials, and the process often involved shredding panels and using harsh chemicals. The new approach recovers over 95% of materials in much better condition. This means the glass, aluminum frames, silicon cells, and even the silver wiring can be extracted intact and reused in new products—including new solar panels.

For you as a homeowner, this matters financially. Better material recovery means lower recycling costs and potentially higher resale value for your panels at end-of-life. Some manufacturers are even offering buy-back programs, turning your old panels into a small asset rather than a disposal headache. It’s a win for your wallet and the planet.

Panels Built for Second Lives

The solar industry is rethinking how panels are made from the ground up. Instead of treating them as sealed units destined for disposal after 25-30 years, forward-thinking manufacturers are designing panels that can be taken apart, repaired, and given a second life.

The key innovation is modular design. Think of it like the difference between a smartphone you can’t open and a laptop where you can swap out the battery or hard drive. Some companies now build panels with standardized components—frames, junction boxes, and glass—that can be removed and replaced individually. If one part fails, you replace just that piece rather than tossing the entire panel.

This approach tackles a common myth: that solar panels create mountains of waste. The reality is that most panels don’t actually “die” at 25 years. They simply produce slightly less electricity, often still generating 80-85% of their original output. With modular design, these panels can be refurbished with new components and redeployed in less demanding applications, like powering garden lights or charging stations in developing regions.

For you as a homeowner, this means better long-term value. Panels built with replaceable parts may cost slightly more upfront, but they protect your investment. If technology improves or a component needs updating, you won’t need a complete system overhaul. Some manufacturers even offer trade-in programs, buying back your older modular panels for refurbishment and giving you credit toward new ones—turning your roof into a renewable resource in more ways than one.

Advanced Recycling Technologies

Think of advanced recycling technologies as sophisticated sorting and recovery systems—like high-tech treasure hunters that can pick out valuable materials from old solar panels with remarkable precision. These new methods are transforming what was once considered waste into a goldmine of reusable resources.

Traditional recycling often settled for recovering just aluminum frames and glass, leaving behind valuable materials. Today’s chemical and thermal processes work more like precision extraction tools. They can recover up to 95% of materials from retired panels, including silicon wafers, silver contacts, copper wiring, and other precious metals that make solar technology work. To put this in perspective, a single panel contains about 20 grams of silver—multiply that across thousands of panels, and you’re looking at significant value.

The process itself is surprisingly straightforward in concept. Thermal methods use controlled heating to separate different materials based on their melting points—think of it as carefully peeling apart layers of a cake. Chemical processes work more like selective filters, using safe solutions to dissolve and recover specific materials while leaving others intact. These recovered materials often match virgin quality, meaning they can be used in new panels or other electronics without any performance compromise.

Several companies now offer these services commercially, with some achieving recovery rates that seemed impossible just five years ago. This matters for homeowners because manufacturers using these advanced materials and recycling partnerships can offer better warranties and take-back programs. You’re not just buying panels—you’re investing in a system designed to retain value throughout its entire lifecycle, with materials that will live on long after your installation reaches retirement age.

What This Means for Your Home Solar Investment

Choosing circular-designed solar panels isn’t just good for the planet—it can significantly boost your bottom line and home value. Here’s what these innovations mean for your wallet.

Several solar manufacturers now offer buyback programs for end-of-life panels. When your system needs replacement in 25-30 years, these companies will take back your old panels and credit you toward new ones. Instead of paying disposal fees (which can run $20-30 per panel), you’ll receive value back. Some programs offer credits of $50-100 per panel, effectively reducing your future upgrade costs by thousands of dollars.

Extended warranties are becoming standard with circular-designed systems. Manufacturers confident in their recyclability and durability are now offering 30-35 year warranties instead of the traditional 25 years. This extended coverage protects your investment longer and signals higher quality construction—benefits that directly impact your solar investment benefits.

Your home value gets a measurable boost too. Studies show homes with solar systems sell for 4-6% more than comparable properties. As sustainability becomes a bigger priority for homebuyers, having a certified circular-designed system adds an extra selling point. You’re not just offering clean energy—you’re demonstrating forward-thinking environmental responsibility that resonates with eco-conscious buyers.

Lower replacement costs down the road mean better long-term financial planning. Circular designs use fewer rare materials and more standardized components, which manufacturers expect will reduce future panel costs by 15-25%. When you eventually need replacements or expansions, you’ll benefit from this price reduction.

The takeaway? Circular solar panels deliver immediate environmental benefits while protecting your financial future through buyback options, longer warranties, and increased home value.

How to Choose Solar Panels with Circular Design Today

When you’re ready to invest in solar panels, finding options designed with circularity in mind requires asking the right questions and knowing what to look for. Start by asking potential installers if they offer panels from manufacturers with take-back programs or recycling partnerships. Companies like SunPower, REC Group, and First Solar are leading the way in circular design practices, offering extended warranties and end-of-life solutions.

Look for certifications that signal environmental commitment. The Cradle to Cradle Certified program and ISO 14001 environmental management certification are good indicators. Also ask whether the manufacturer uses recycled materials in production and if they’ve designed their panels for easier disassembly.

Key questions to ask your installer include: What happens to my panels after 25-30 years? Does the manufacturer participate in recycling programs? Are replacement parts available if needed? What percentage of the panel can be recycled?

Consider the total lifecycle value, not just upfront costs. While panels with circular design features might cost slightly more initially, they often come with better warranties, higher quality materials, and guaranteed recycling services that protect your long-term investment.

Many of the latest solar technologies incorporate circular principles by default, so you’re likely to find these features in cutting-edge products. Request documentation about the manufacturer’s sustainability commitments and recycling capabilities before making your final decision. Your choice today can help shape a cleaner solar industry tomorrow while securing reliable home energy for decades.

Choosing circular solar panels isn’t just good for the planet—it’s a smart financial decision that protects your investment for decades to come. By supporting manufacturers who design for recycling and take responsibility for their products’ entire lifecycle, you’re helping build a solar industry that truly lives up to its green promise. The good news? You don’t have to sacrifice performance or pay premium prices to make the sustainable choice. As circular design becomes standard practice, you’ll benefit from panels that last longer, hold their value better, and come with transparent end-of-life solutions. This means lower energy bills today, potential rebates and incentives, and the satisfaction of knowing your clean energy system won’t become tomorrow’s landfill problem. The future of solar is circular, and it’s already here—powering homes responsibly while creating a cleaner legacy for the generations who’ll inherit the planet we’re protecting today.